2.4 TILE RACKS AND PALLETS

After the tile is pressed and trimmed, it must be thoroughly dried before firing (see Operation

of a tile production unit). Exactly how long this drying takes depends greatly on the moisture

content of the clay, the particle size of the clay composition, the thickness of the tile, and the

prevailing weather conditions of the area. In very hot areas a tile may dry in five days, while

ten days may be required under some conditions. With an output of around 5,000 tiles per

day it is clear a factory must have room for between 25,000 and 50,000 tiles in its drying

racks. Drying racks and pallets are one of the more expensive elements in a tile factory, so

careful planning is called for.

The racks are typically built up to 14ft high to conserve factory space, usually against outside

walls for easy access and exposure to drying breezes. To stack tiles, boards are put across the

aisle, resting on the stringers of the racks. Since the racks will be holding hundreds of tiles

and one or more people handing tiles up, they must be sturdy. Uprights are placed on

approximately 1.5m centre, and one built from 5cmxl0cm lumber (see figure 27). The

stringers are notched and nailed into the uprights and one made from 3cmx6cm lumber. The

aisles are around 1.5rn wide to allow adequate space for loading and unloading of the racks.

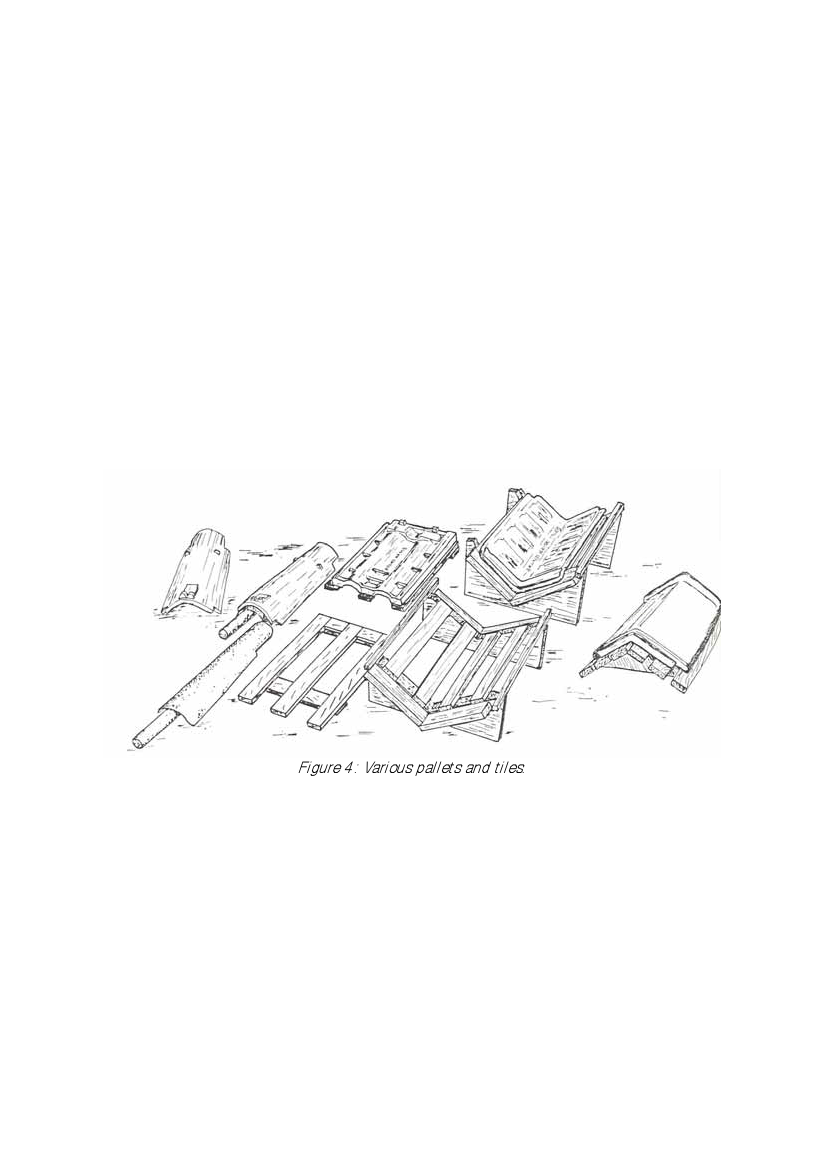

Figure 4: Various pallets and tiles.

Wet tiles must be placed directly from the press onto a pallet to maintain their shape (see fig.

4). Some Roman-type tiles can be placed directly on a flat surface after trimming, but all

larger modern tiles must be kept on pallets until firing. The pallets must be sturdy so that

they can be carried without damaging the wet tile. A well-made pallet will last over 10 years

in constant use. By coating the pallet periodically with used engine oil, it can be preserved

from insects. This allows the tile to slide as it shrinks during drying. Special pallets holding

ridge tiles can be stacked upon each other, without racks, to about two meters high (see fig

6).

Tiles can be moved with a wheel cart: the cart holds the tiles on half inch (lcm) diameter

steel rods and is easily handled by one person (see fig. 5).